Grinding and Polishing Laps for the CutKit (6 inch laps)

Grinding and Polishing Laps for the CutKit (6 inch laps)

833 in stock

Couldn't load pickup availability

These are cutting and polishing laps for the CutKit™.

We have both 6 inch diameter toppers which are placed on the master lap and 6 inch solid sintered laps.

Sintered laps have a high concentration of diamond mixed with bronze in a thick layer. They last basically forever--they are less aggressive than a topper of the same grit and leave a smoother finish.

Note the sintered laps are thicker than our other laps but the center of the lap is actually thinner. Each lap comes with a spacer to allow the lap nut to lock it in place, plus a flexible plastic sheet with two clips--this can be clipped onto the machine's water shield to reduce the extra spray caused by how thick the sintered laps are.

The 100 grit sintered lap is good for rough cutting, but cuts more like a 240. The 600 is great for final placement of facets and leaves an excellent surface for a fast prepolish. These laps can glaze over time and slow down (particularly when cutting large moissanites!)--I have run a 1000 grit whetstone over mine while spinning with a good water drip and that rapidly brought it back to its original speed

100 grit topper laps are good for extra-coarse roughing of very large stones like dice.

240 grit topper laps are good for coarse shaping of a stone--I almost never place all the facets with a 240, just a few to get the stone preshaped.

600 grit laps are used for placing facets close to their final position. These laps should be broken in with a piece of corundum, as they will typically cut a little too aggressively when fresh.

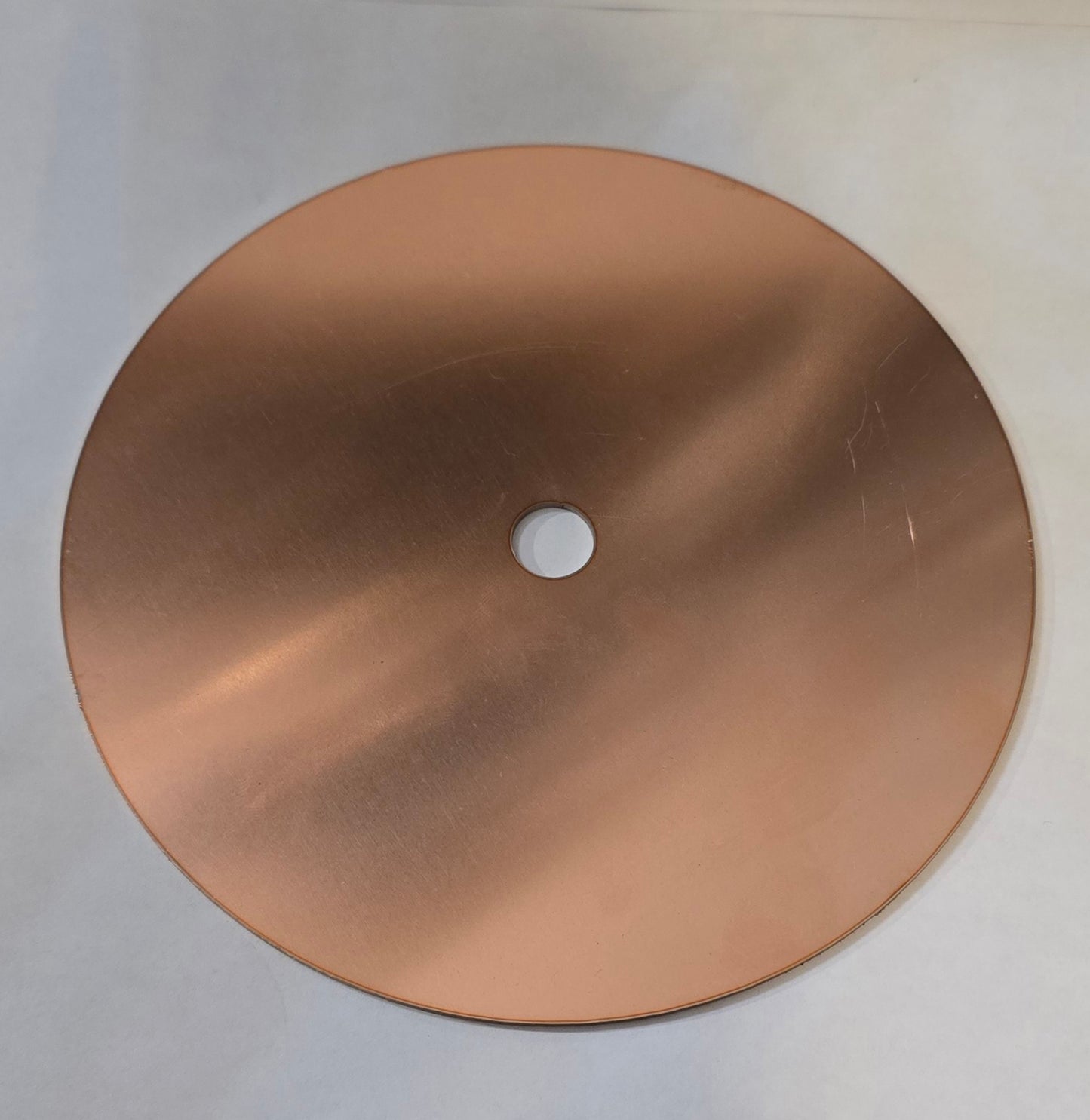

Copper laps are charged with diamond grit (best of all, Gearloose™ Diastiks) and used for prepolish and polish. These sometimes arrive with scratches--don't be concerned, they come from the factory that way. Copper laps tend to perform best when scored, putting intentional scratches into the surface to help retain diamond and increase surface complexity. Here is a video on the topic by Justin K Prim.

Share